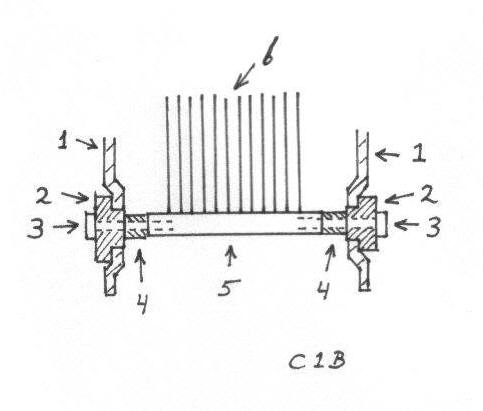

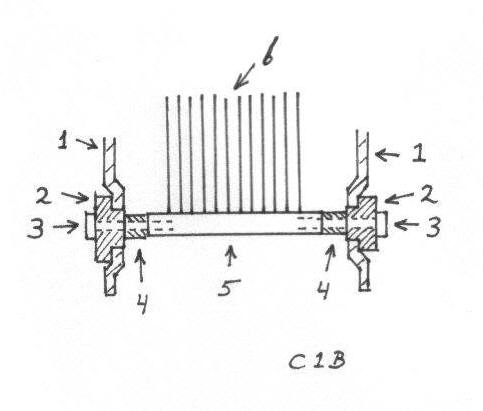

1= frame of tuning capacitor

2= plastic insulation ring

3= nylon screw

4= polyethene insulation block

5= copper connection bar for stator plates

6= stator plates

Experiments with LC circuits part 4

<< Go to part 3

Go to part 5 >>

Back to the index

From tuning capacitor C1b I now removed the insulation rings which keeps the

stator on it's place.

I found that the used nylon screws gave some dielectric losses which reduces

circuit Q.

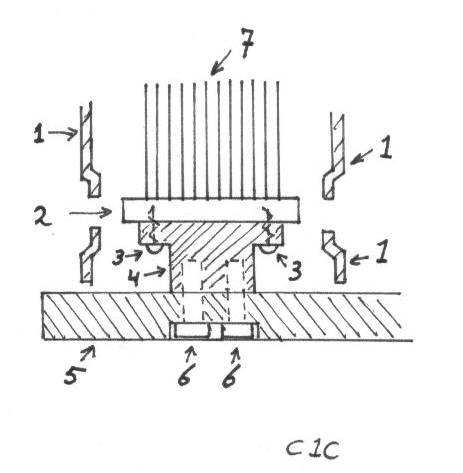

Now I use instead a polyethene block which supports the stator from the

underside.

In the following drawings this is shown., this version of tuning capacitor I

call: C1c.

|

Tuning capacitor C1b

1= frame of tuning capacitor |

|

Tuning capacitor C1c

1= frame of tuning capacitor |

The plastic insulation blocks of tuning capacitor C2 are replaced by polyethene blocks (which are the green blocks on the next picture).

| Left: C1c (495 pF).

Right: C2a (390 pF). |

After these changes, I measured the Q's again, they were increased.

The percentages of increase are also mentioned, compared to measurement 21 and

22.

|

Measurement |

LC combination |

F min |

F max |

Q |

Q |

Q |

Q |

|

23 |

L9 C1c |

542 |

2349 |

1072 |

947 |

815 |

658 |

|

24 |

L9 C2a |

606 |

2400 |

1143 |

1000 |

833 |

632 |

Now I have drilled a lot of 2 mm holes in the polyethene insulation blocks of

tuning capacitor C2a.

Hoping that removing insulation material will reduce dielectric losses even

more.

This version of tuning capacitor is called: C2b.

|

Measurement |

LC combination |

F min |

F max |

Q |

Q |

Q |

Q |

|

25 |

L9 C2b |

600 |

2382 |

1052 |

1000 |

875 |

714 |

The percentages mentioned are compared to measurement 24.

At 600 kHz there is a decrease in Q, how that comes, I don't know.

Maybe there was a measuring error in measurement 24, normally the accuracy of the

measured values are I think between +5% and -5%, but maybe this time the error

is higher.

Or maybe the Q is really reduced at 600 kHz, this is no problem, at low

frequencies a Q above 1000 is more than enough.

"Tot lering en vermaak" That's an old Dutch expression which

means "for learning and fun".

And that's why I made the following two measurements with lower Q coils, often

used in crystal receivers.

| Coil L10 13 meters litzwire 40x0.07mm on a former made of a CD. The shiny aluminium layer is fully removed from the CD. Coil L11 |

The used tuning capacitor is C2b.

|

Measurement |

LC combination |

F min |

F max |

Q |

Q |

Q |

Q |

|

26 |

L10 C2b |

530 |

* |

358 | 371 | 346 | 304 |

|

27 |

L11 C2b |

761 |

3270 |

* |

211 |

234 |

241 |

* = not measured.

The measured values are not bad at all, but keep in mind that a very good tuning

capacitor is used.

So, a good comparison with measurement 1 to 16 is not possible, also because the

test method used now is much better.

<< Go to part 3

Go to part 5 >>

Back to the index